Curiosity and clusters

An Indian American inventor known for creating a revolutionary dental filling material that improved the way dentists restore teeth, Sumita Mitra used her curiosity and imagination to discover the idea for the material where she least expected it.

17 min read

Each month, our Journeys of Innovation series tells the stories of inventors or entrepreneurs who have made a positive difference in the world. This month, Alexis Ramos' story focuses on Sumita Mitra, who is best known for creating the first dental filler to include nanoparticles.

Observing the color, texture, imperfections, and composition of the grapes before her, Sumita Mitra saturates her round brush in water, dabs it into violet pigment, and glides it against the watercolor paper using whirlpool motions, emulating clusters of grapes in various sizes.

Putting paintbrush to paper provides Mitra moments of respite from her challenging work in the field of chemistry.

“Most people say [watercolor] is the most difficult technique to use. But I love it because of the way that the colors spread. And you have to be really precise,” she said. “It's not acrylic or oil where you can go over it. You can't go over it when you do watercolor.”

A watercolor painting created and signed by Sumita Mitra captures the blueprint for her dental restorative materials: clusters.

(Courtesy of Sumita Mitra)

Her love for watercolor painting is matched by her favorite art subject- grapes.

“I find [grapes] very beautiful,” Mitra shared.

The grapes, though both beautiful and delicious, are so much more to the painter-chemist.

They inspired her journey to create a new category of dental restoration materials that, over the course of a decade, would provide people with more vibrant, lifelike teeth restorations.

It was the late-1990s and Mitra was standing in the kitchen of her home in St. Paul, Minnesota staring at a bowl of grapes. A chemist in the dental lab at 3M, she recalled plucking a grape from a cluster with her fingertips and reflecting on how dental fillings often became rough and dull-looking with time as particles from them became dislodged, but in this instance, she observed that the grape cluster remained quite intact with no gaping hole left behind.

Each cluster varied in size with some having perhaps 30 grapes, while another having 10 or five. She imagined manipulating nanoparticles to share the same features as an individual grape: round and equally sized. In her lab at 3M, the chemist had already been experimenting unsuccessfully with uniformly sized nanoparticles. She realized there was one thing she hadn’t tried with nanoparticles that could mimic grapes even further.

Nanoclusters.

Instead of using uniform nanoparticles, they could be assembled in various clusters like grapes linked to a vine.

"The whole idea of nanoclusters [is] that they were like a bunch of little nanoparticles that would be clustered together, but could be taken apart one at a time, if required," Mitra explained of her aha moment.

To Mitra, nature and chemistry governed everything. She realized this from a very a young age, influenced by her parents and her hometown. Mitra knew to apply those principles everywhere she went.

Born February 27, 1949, in Kolkata, India, Sumita spent her early years in Arunachal Pradesh where she grew up free to safely roam the remote state known for its lush greenery, variety of wildlife, and rich biodiversity. Being the first soil to greet the morning sun in India’s far northeast, it is often referenced as “the land of the dawnlit mountains.”

Sumita Mitra’s father in his lab. For Mitra, he was one of the many people who inspired her to pursue a career in chemistry.

(Courtesy of Sumita Mitra)

Her father, Pranab, a doctorate in chemistry from the University of Washington with a master's degree in forestry, worked as a chemist in a plywood factory. As a little girl, Sumita would often visit her father in his laboratory as he researched new technologies and scaled them up for manufacture. She’d wonder about what made things like paper and pencil or skin and hair inherently different from each other. It was a form of curiosity and willingness to learn that grew stronger as she got older.

Due to the remote location of where her family lived, Sumita was homeschooled by her mother, Arati. Later, when the family moved to Kolkata and she attended secondary and high school there, her mother continued to tutor her.

She was “probably the most influential person in my life,” Mitra said, adding that her mother’s own educational pursuits were upended by challenging circumstances.

During the Partition of India in 1947, Mitra’s mother and her family became refugees, fleeing the upheavals of the established borders. As a result, she was unable to finish her college education, a regret she vowed would not be repeated.

“She got married, then I was born. So, she was bound and determined that I was going to get the best education possible and have a meaningful career myself. She instilled into me from a very young age that kind of an expectation,” Mitra said.

She would not disappoint.

In 1969, Mitra received her bachelor's degree from Presidency College in Kolkata. It was also where she met her future husband, Sam. Later, in 1972, she received her Master of Science degree in organic chemistry from the University of Calcutta. Ready to take on the next educational challenge, Mitra planned to follow in her father’s footsteps by pursuing further studies in the United States but was met with strong resistance from some corners of her family.

“At the time, it was uncommon for young women to have science careers or to travel long distances unaccompanied and unmarried to study,” she explained of her family’s reluctance to support her move.

Mitra pushed back against the opposition using lessons taught by her parents and the inspiration of an old photo.

Her mother encouraged her to take everyone’s perspectives into account while remaining true to herself while both parents encouraged her not to let fear get in the way of her pursuits.

Mitra recalled a photograph she once saw of her father standing proudly along the pedestrian walkway of the Golden Gate Bridge in San Francisco during his own studies in the United States. The photo left an impression on her which turned into determination.

“I remembered [seeing that picture and] thinking to myself, ‘I’d like to see the Golden Gate Bridge too!’” she said.

Mitra left for the United States in 1972 where she began her studies at the University of Connecticut before transferring to the University of Michigan to join Sam.

After graduating with a Doctor of Philosophy degree in organic/polymer chemistry in 1977, she joined the Corporate Research Laboratories at 3M in 1978 following a year of post-doctoral work in the Macromolecular Science and Engineering department at Case Western Reserve University. That same year her husband Sam joined her at 3M as a chemist in a different lab that specialized in polymer synthesis.

Young Sumita Mitra with her mother. The future chemist recalled her mother teaching her to always, “be more prepared than everyone else,” when it came to working hard and seeking a meaningful career.

(Courtesy of Sumita Mitra)

Arriving at 3M Corporate Research Labs, Mitra said she had no expectations of feeling different from her peers, but as one of the only women of Asian descent in the room, the differences couldn’t be overlooked.

Her experience wasn’t uncommon during that time.

According to a 1970 U.S. Census, scientists who identified as white male made up of 79.85% versus 0.58% for those who reported identifying as Asian female.

Again, homing in on her mother’s advice to “stand up tall, stay positive,” Mitra committed herself to finding projects and work that would bring value to 3M across various businesses. She focused on projects that could spread into different areas of the company so that the investment would be worth it.

“So, just one product or one application is not an efficient use of people's time. And I didn't want that for myself. I wanted to do work that could create technology platforms, which could benefit many parts of the company,” she shared.

Five years into her career at 3M Corporate Research Labs, Sumita had patented several inventions, including one for copolymerizable UV stabilizers with her husband, Sam. It was the first time in 3M history where a husband and wife patented an invention together.

“We talked about chemistry [at home], both his work and my work. We still do. It’s really nice to have someone to bounce ideas off [with]. We are kind of a little nerdy if you were,” she joked.

Seeking something new, she transferred from the Corporate Research Laboratories to the Dental Products Division.

“At the time, the Dental Products department was small and quite new, but it was a risk I was willing to take for the opportunity to be closer to the customers,” she said, adding that her boss thought she was being irrational for making the transfer.

The Dental Products department heavily depended on listening and learning from their customers using in-house and third-party surveys, focus groups, and hands-on evaluations. This close connection to product end users would provide Mitra an opportunity to have a positive and direct impact on individuals as well leave her mark in the dental industry, which has gone through an evolutionary process with teeth restoration materials for centuries.

In the early 1800s, amalgams — alloys of different metals with mercury — were used as dental fillings, which led to controversy due to reports of adverse health effects. By the late 20th century, the safest and routine treatment to restore teeth was using two different tooth-colored dental composites — microfills and hybrids — to achieve certain outcomes for different parts of the mouth. This method, however, still had many limitations.

Hybrid composites, which are still used today, are made up of mixtures of large and small filler particles to provide strength. They are mainly used for the back teeth, but oftentimes could wear away and allow large particles to pop off. Microfill composites, typically used for front teeth restorations, are made up of small filler particles. It provides smooth and polished fillings but does not have adequate strength for the biting surfaces of teeth. To obtain optimum results in many cases, layering of the two materials would be needed resulting in a time-consuming process.

Sumita Mitra and her husband Sam Smarajit pose before her exhibit at the National Inventors Hall of Fame Museum.

(Courtesy of the National Inventors Hall of Fame)

“I thought, really what [dentists] needed was a filling material for universal use. Something that could be used for all locations of the mouth and that could have both lasting beauty, abrasion resistance, and physical strength to withstand chewing forces,” she explained.

Mitra wanted to incorporate nanotechnology, then an emerging branch of science and engineering, in her quest for a much improved material. For chemists like Sumita, nanotechnology was a new opportunity to learn something new and use it for developing dental filling materials. She took her cue from the construction of natural teeth, which is a nanostructured material in itself.

Together with a team of researchers in the Dental Products Laboratory she started to synthesize nanoparticles of various oxides that were well below 100 nanometers. They then incorporated these particles into resins to create composites. Although the composites they initially made had excellent strength and esthetics when cured, they suffered from the drawback that they were difficult to handle and shape in the uncured form. This was inconvenient for the dental practitioner. It was a trial-and-error process that required determination to keep going — and, again, Mitra heard the voice of her mother encouraging her to “stay laser focused, and a solution will emerge.”

Which brings us back to the bowl of grapes.

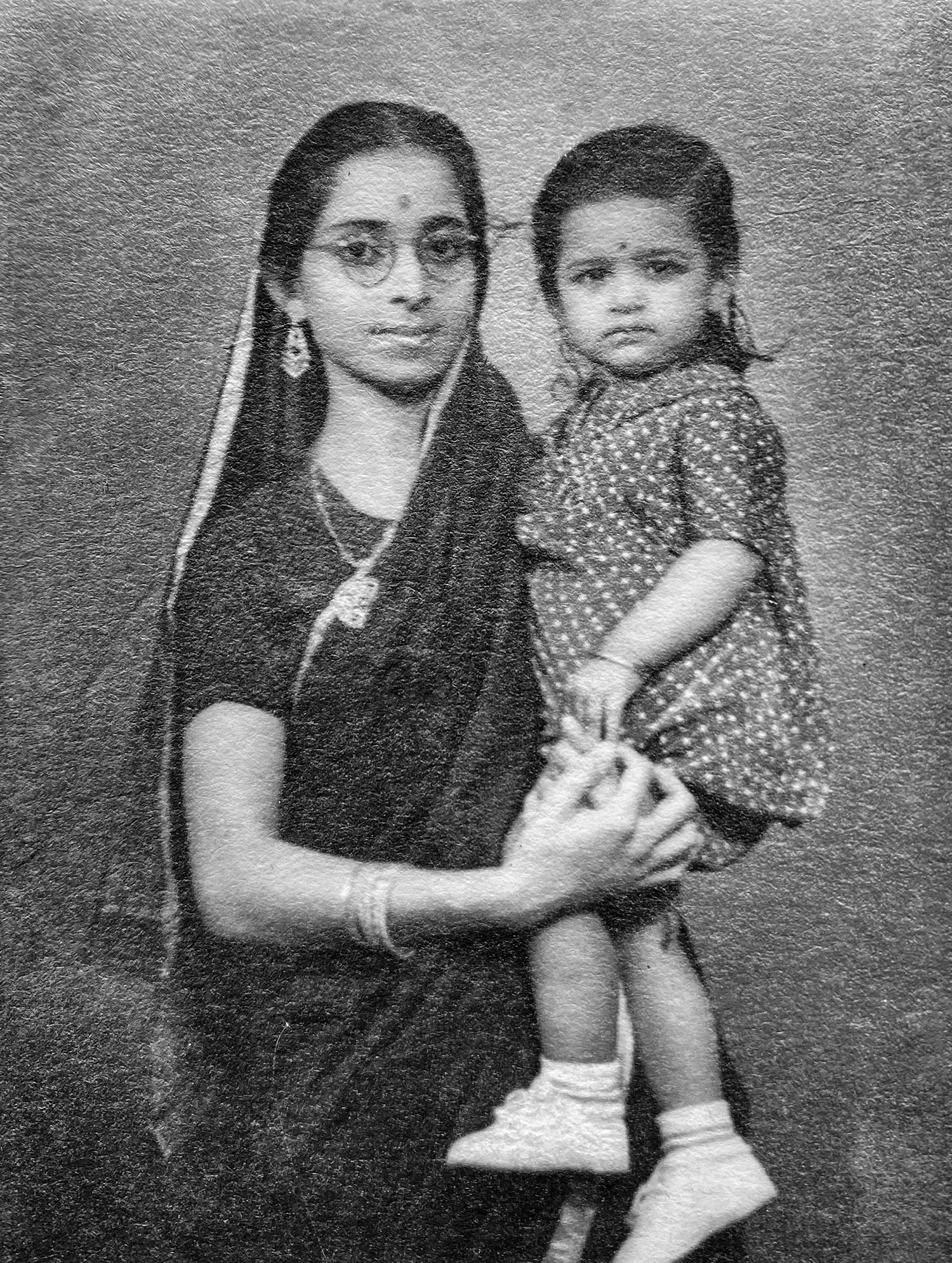

Upon conceiving her grape theory to use nanoclusters — nanoparticles clustered together — to create the material, Mitra joined forces with her fellow scientists and engineers. Two types of nanoparticles were mixed together clustered by a thermal process: silica for an enhanced bonding strength and zirconia for radiopacity — a characteristic needed for dental x-rays. These nanoclusters were then mixed with unagglomerated — or scattered — nanoparticles and the combination formulated with resin to yield a nanocomposite. The University of Minnesota’s School of Dentistry’s Minnesota Dental Research Center for Biomaterials and Biomechanics (MDRCBB), where she served as industrial director from 1999-2010, also played a pivotal role in the research thanks to the facility’s equipment to help test the team’s work.

Taken at 300,000x magnification, nanoparticles are seen as clusters. These nanoclusters provide dentists with a dental material that can be used as restoratives, adhesives, cements, orthodontic devices, mil blanks, and prostheses.

(Patent No. US6387981)

“The innovative evaluative techniques like the ART (Artificial Resynthesis Technology) chewing machine, simulated toothbrushing machine, fracture toughness of pristine and stress materials, and more at the Center helped us to quickly study hundreds of different formulations and identify suitable candidates for future development,” she shared with MDRCBB about her experience.

It was also the people she worked alongside, describing that it “felt like we were on the same team.” One colleague she worked closely with, Dr. William Douglas, shared with MDRCBB that during his time working alongside Mitra, the pair would use code names for the materials they were developing like "Nautilus" and "Basketball" to protect their intellectual property.

While there were many challenges Mitra faced while working in the Dental Products Division, one of the biggest hurdles of her career was convincing management to take a chance on this new experimental material by investing the money to build manufacturing facilities that could scale the product for commercial use.

“It's always easier to keep doing what you're doing and [take baby steps] toward advancement,” she explained of the typical approach that management was comfortable undertaking when investing in new projects. “But that is not what I wanted to do. I wanted to do something that was really transformational."

With the help of prospective customers who believed in the new composite, and Mitra's ability to communicate the long-term goal instead of the short-term goals, she was able to convince management to continue funding the project and make the needed investments for scaling up the process for manufacturing the material.

In 2002, Mitra’s nanocomposites made of nanomers and nanoclusters were manufactured and commercialized. This resulted in a material for tooth restoration that had the strength, beautiful shine, and durability of natural teeth. In 2002, her invention for a dental composite resin for tooth restoration was granted several patents and 3M's Oral Care division sold it as FiltekTM Supreme Restorative. Over the next decades, the product would continue to evolve, including optimized shades and fluorescence to provide more vibrant, lifelike teeth restorations for dental patients. The family of Filtek products has been used to restore well over one billion teeth globally.

“It was a very momentous event for me,” Mitra shared with Inventors Digest. “The issuance of the patents validated the novelty and utility of our work and allowed us to go forward with the commercialization process.”

Described as a “trailblazer of dentistry” by a colleague, Mitra went on to receive many accolades for her contributions.

In 2018, she was inducted into the National Inventors Hall of Fame for her work on the nanocomposite dental materials. In 2021, she was elected a member of the National Academy of Engineering (NAE), among the highest professional distinctions for engineers, elected as a fellow in the National Academy of Inventors, and honored with the European Inventor Award.

“Her enduring contributions to 3M Oral Care illustrate the power of a collaborative team of scientists working together, using 3M technologies, to create innovative solutions that help ensure better health for all,” 3M shared in a press release announcing her acceptance into the NAE.

Mitra retired from 3M in 2010 and now lives in Florida. In 2021, she was appointed as a professor at the University of South Florida’s Institute of Advanced Discovery and Innovation.

Sumita Mitra doubted dental treatment was top of mind for Richard Feynman, father of nanotechnology, when he gave his famous speech "There’s plenty of room at the bottom," but she made room for it anyway. She was inducted into the National Inventors Hall of Fame in 2018.

(Courtesy of the National Inventors Hall of Fame)

She enjoys the pleasures of traveling and spending time with her family.

“It was a treat this summer to travel with my daughter’s family and have my granddaughter with us. She turned 10, and that's a sweet age,” she shared of her recent trip to France and England. “I have two sets of cousins who I hadn’t seen for ages, so we thought we would also visit them. It was a wonderful trip.”

She also hasn’t stopped learning and continues to nurture her child-like curiosity and exploration by belonging to the Academy of Senior Professionals at Eckerd College (ASPEC), a lifelong learning program in St. Petersburg, Florida that supports intergenerational learning.

“There are [interest groups] like philosophy, science, medical topics, legal topics, literature, art, and more. You name it, we have it. So, I'm very involved in that. And this is a five-days-a-week program,” she said.

Through ASPEC, Mitra has not only been able to fuel her passion for chemistry, but also for watercolor painting by learning from retired professional artists.

“One of our members is an artist whose work is displayed in New York galleries,” she said of the prestigious individuals she has the pleasure to learn from. “So, we learn from each other. I've dabbled in other art media, but I like to stay with the watercolors.”

The retired chemist also co-chairs an interest group called Science and Society, one of 40 active interest groups in the academy, where she challenges others to embrace their curiosity about the world.

“[I teach in] different areas, whether it's material science, biochemistry, or genetics and [I ask], ‘how does science impact society?’” she said.

Because of her association with Eckerd College, Mitra also interacts with the students and faculty where she has the pleasure of evaluating capstone projects and presentations, and mentoring students.

Over the last 40 years, the chemist has witnessed the evolution of her field and said that classical material science — or fundamental chemistry — has helped form many new technologies.

“Nanotechnology is not really a classical chemical technology, but it starts with the basic principles of chemistry and blends it with other types of material science,” she said.

Through these new technologies, Mitra has seen a shift in the way today’s scientists are thinking about sustainability and preparing for a better tomorrow.

Mitra continues to work with several organizations including the National Inventors Hall of Fame, Collegiate Inventors Competition, and the Camp Invention program. When asked about the next generation, Mitra said she is “confident that we will be left in good hands.”

(Courtesy of the National Inventors Hall of Fame)

“One of the things that I see a lot now, in the last five years probably, is the focus now shifting to studying and improving the field of critical materials...[there is a] shortage of things like lithium and cobalt, nickel, gallium, all of these materials that are going to be materials of the future,” she said.

She explained how these elements are needed for battery and other technological advancements:

“There's a lot of effort now going into more efficient extraction chemistries, while looking at a circular economy for recycling materials, keeping an eye on the environment.”

Working alongside the National Inventors Hall of Fame and its Collegiate Inventors Competition and Camp Invention program, Mitra said she is excited about the future.

“I’m confident that our legacy will be left in good hands,” she said of the next generation of inventors. “It's so refreshing to be with them. They are so curious and they want to learn. It's just a joy to be with these kids and to think they're the future of our society."

Just like the next generation of inventors she described, Sumita upheld her own curiosity through her adult years. It is what bound her to her discovery within the clusters of grapes and shows that with a little curiosity and determination, there is an answer waiting to be discovered anywhere.

Credits

Produced by the USPTO’s Office of the Chief Communications Officer. For feedback or questions, please contact OCCOfeedback@uspto.gov.

Story by Alexis Ramos. Additional contributions from Whitney Pandil-Eaton, Jennifer McIntosh, Laurel McKenzie, and Paul Rosenthal. Special thanks to Sumita B. Mitra, Rini Paiva, and Ken Torisky.

References

Sheridan, Kate. “Meet the Woman behind the Nanotechnology That Revolutionized Dental Care.” Newsweek, May 1, 2018. https://www.newsweek.com/2018/05/11/meet-woman-behind-nanotechnology-re….

Mathur, Preeti. “From the Ganges to Ten Thousand Lakes: Immigration from India to Minnesota | MNopedia.” MNopedia, Minnesota Historical Society., n.d. https://www.mnopedia.org/ganges-ten-thousand-lakes-immigration-india-mi….

The Global Indian. “Sumita Mitra: The Indian American scientist behind 1 billion flawless smiles,” April 26, 2021. https://www.globalindian.com/story/technology/sumita-mitra-the-indian-a….

Dental Advisor. “3M FiltekTM Supreme plus and 3M FiltekTM Supreme Ultra Universal Restorative.” Dental Advisor, April 16, 2018. 3M FiltekTM Supreme Plus and 3M FiltekTM Supreme Ultra Universal Restorative.

Sumita B. Mitra, interview by Alexis Ramos, January 9, 2024.

Sumita B. Mitra, interview by Alexis Ramos, February 29, 2024.

Sumita B. Mitra, interview by Alexis Ramos, July 1, 2024.

3M. “Filtek Universal Restorative Technical Product Profile.” 3M, n.d. https://multimedia.3m.com/mws/media/1651107O/3m-filtek-universal-restor….

“Nanoscale Dentistry. Big Results. Take a Closer Look at 3M’s Nanofiller Technology and the Future of Dentistry.”3M. https://cdn.vivarep.com/contrib/vivarep/media/pdf/2_6214_FiltekUniversa….

Agre, Mark. “What’s in Your Composite? Get Filled in on Fillers.” 3M Dental Blog, September 1, 2020. https://dentalblog.3m.com/dental/whats-in-your-composite-get-filled-in-….

“Curiosity and Exploration: The Sumita Mitra Story.” 2018. YouTube. National Inventors Hall of Fame. May 7, 2018. https://www.youtube.com/watch?v=_2oNxvsZSNs

LIVE at the National Inventors Hall of Fame Induction Ceremony!” 2018. Facebook. National Inventors Hall of Fame. May 3, 2018. https://www.facebook.com/InventorsHOF/videos/live-at-the-national-inven…

“Sumita Mitra - Restoring Smiles with Nanomaterials.” 2021. YouTube. European Patent Office. May 4, 2021. https://www.youtube.com/watch?v=ySQqhk7Xrg0.

Zhang, X., et al., Kolb, U., E., Hanggi, D., Alan, Basu, S., Mitra, P., D’Nell, & Rusin, R., Paul. (2002). RADIOPAQUE DENTAL MATERIALS WITH NANO-SIZED PARTICLES (Patent No. US 6,387,981 B1). In United States Patent (US 6,387,981 B1). United States Patent. https://patentimages.storage.googleapis.com/1b/90/03/90412a602ff23c/US6…

The National Academy of Engineering elects former 3M scientist, Sumita B. Mitra. (n.d.). MMM-ext. https://www.3m.com/3M/en_US/health-care-us/stories/full-story/~/the-nat…

European Patent Office. (2021, May 4). Restoring Smiles with Nanomaterials: U.S. Based Chemist Sumita Mitra Named European Inventor Award 2021 Finalist [Press release]. https://www.prweb.com/releases/restoring-smiles-with-nanomaterials-u-s-…

Alumna Sumita Mitra Inducted into National Inventors Hall of Fame | U-M LSA Chemistry. (n.d.). https://lsa.umich.edu/chem/news-events/all-news/search-news/alumna-sumi…